Why isn't my simulation running in SolidWorks?

1. Scan Engine is not in Active Mode

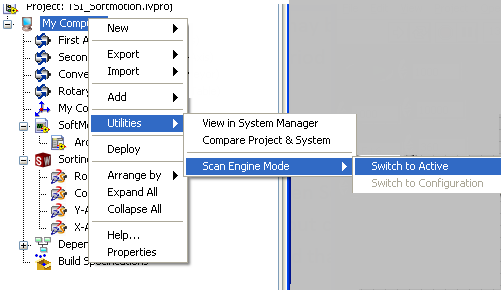

When running a simulation, you must have the Scan Engine in Active Mode, rather than Configuration Mode. To switch between the two is simple: just right click My Computer»Utilities»Scan Engine Mode»Active Mode:

Whenever any configuration changes are deployed, the Scan Engine will automatically switch back into Configuration Mode. If the deployment operation did not cause the Scan Engine to transition to Active Mode, you must ensure to set it to Active Mode before running your code.

2. Drive is not enabled.

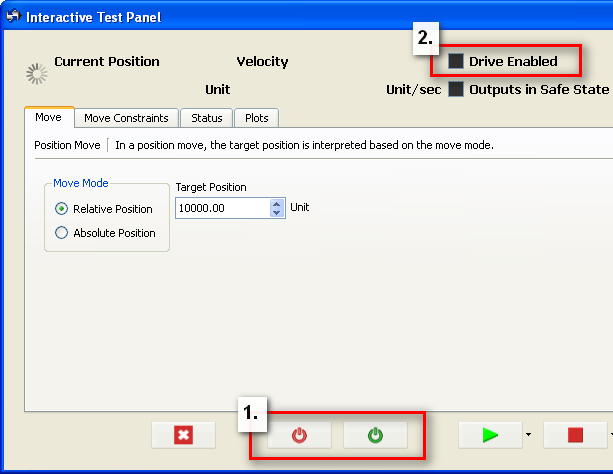

Your drive must also be enabled whenever you are commanding a move. There are two ways to enable the drive. One of these is through the Interactive Test Panel for each axis. Right click on the Axis in your project and choose Interactive Test Panel. The buttons on the bottom (#1 in the figure below) can be used to enable or disable the drive. Once enabled, the Drive Enabled indicator (#2 in the figure below) should be green.

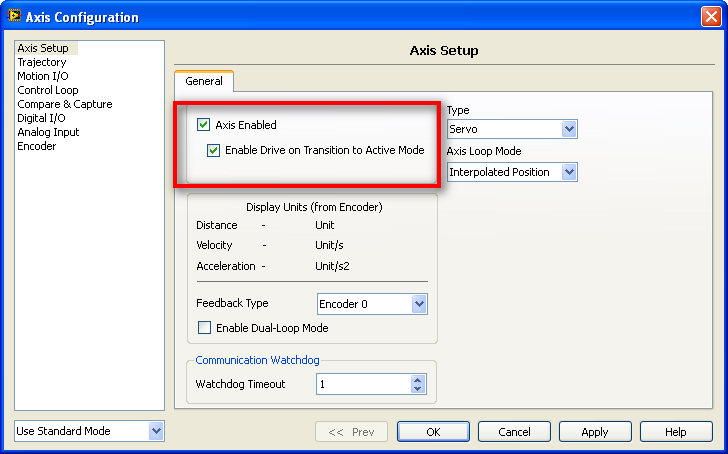

To ensure that the drive is enabled each time you switch to Active Mode, you can check Enable Drive on Transition to Active Mode. This is found in the Axis Configuration dialog for each axis in your project (right click Axis»Properties to pull up the Axis Configuration dialog).

3. SolidWorks Assembly is Out of Date

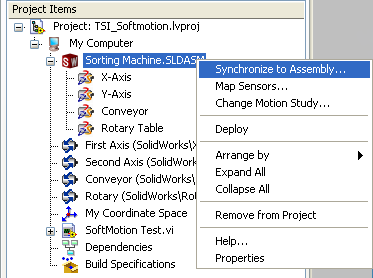

The SolidWorks Assembly in the LabVIEW project and in SolidWorks must match. If any changes are made to the assembly in SolidWorks, you must also apply the changes to LabVIEW. To do this, simply right click on the SolidWorks Assembly in the LabVIEW project and choose Synchronize to Assembly.

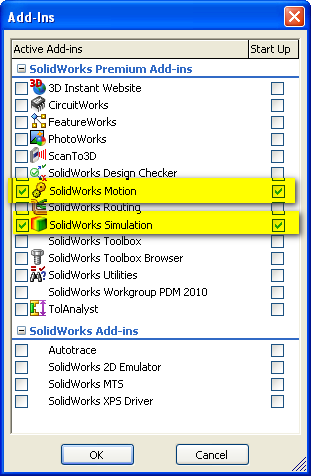

4. SolidWorks Add-In not enabled

To use SoftMotion with SolidWorks, you must activate the SolidWorks Motion Add-Ins. To do this, select Tools»Add-Ins in SolidWorks and check the boxes for Start-Up to ensure that you don't have to re-enable the add-in every time you restart SolidWorks. Note that you must have SolidWorks Premium to have the SolidWorks motion add-in option. See the SolidWorks getting started guide for more information.

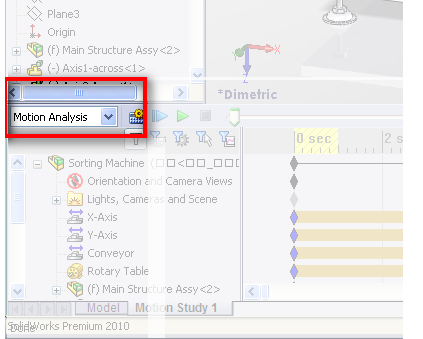

5. Incorrect Type of Motion Study

For the LabVIEW SoftMotion Module to function with SolidWorks, the Type of Study must be Motion Analysis. You can change the type of motion study in SolidWorks, as shown below.

Note that the Motion Analysis option will not be available until the Motion Add In has been activated (see step 4).

6. SolidWorks Assembly uses unsupported motors.

SoftMotion for SolidWorks only works with motors configured as motor type distance. Ensure that you are using the proper type of motors in your assembly. By default, when adding a motor to a SolidWorks assembly, it will be a Constant Speed motor. This must be changed to distance mode to interact properly with LabVIEW SoftMotion for SolidWorks.

7. The maximum integrator step size is greater than the scan engine scan period.

Decrease the maximum integration step size by right-clicking the SolidWorks Assembly project item and selecting Properties.

8. There is a fault on the axis.

Check the interactive view to see what fault has occurred.

Why is my simulation running so slowly, or why does my simulation stop after long periods of time?

Computer does not meet requirements.

It is possible that you have run out of RAM to run the simulation. SolidWorks recommends 6GB of RAM or more on a Windows 7 x64 operating system for optimal performance. See the linked website for more details about the minimum and recommended system requirements for SolidWorks.

Why am I seeing unusual readouts in my SolidWorks simulation?

1. Motor conversion rates incorrect.

Check to ensure that your motors are set up with the proper conversion rates. For a linear motor, this is assumed to be 1 count/mm for encoder counts/unit. For a rotary motor, this is 1 count/degree for encoder counts/unit.

2. Scan periods set too fast.

Because of the intensity of the calculations required to perform a SolidWorks simulation, the speed of the models movements may appear to be slower than real life. These movements are correct with respect to simulation time. Setting a slower scan period will speed up the simulation speed. The scan engine period is set in the target properties of the LabVIEW project (right-click My Computer»Properties or RT Target»Properties).