Solution

The controller (NI 73xx motion controller's family) compares the feedback signal to its commanded signal to verify that the motor is following the command. The difference between these values is called the following error.

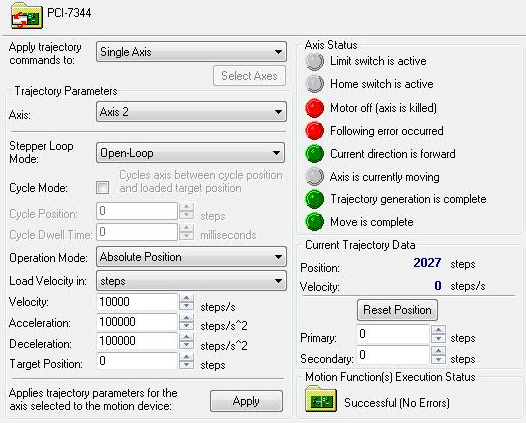

Following Error showing up in MAX

Why does my application report that the following error limit has been exceeded when I command a move?

There is an adjustable limit to the allowed following error during a move. When the limit is exceeded, an error condition is created that reports a fault on this limit. A following error condition can be caused by any combination of mechanical defects, improper inputs/outputs, and control loop flaws. Although following error conditions can be difficult to debug, the most common causes are listed below:

- Cause 1: Encoder input resolution is set incorrectly

To increase feedback accuracy, NI motion controllers read every edge of an encoder feedback signal. With a quadrature encoder, this results in four edges (rising and falling on lines A and B) for every quadrature pulse of the encoder. Thus, if your quadrature encoder is rated at 2000 quadrature pulses per revolution, the controller will actually read 8000 edges per revolution – and each of these is considered a count.

If the polarity of your encoder is reversed, you can also switch the polarity in MAX. To change the polarity of your encoders, select the axis on which the problem is occurring and find the encoder entry. On the encoder tab change the polarity of either A or B, but not both and the index if it is being used.

- Cause 2: Command or feedback wires are reversed

When a command is issued in the positive direction, does the feedback signal return a positive movement? If the feedback signal indicates negative movement, either the polarity of the analog output to the motor or the phase (A, B) of the encoder has been switched. Verify the proper wiring connections to remedy this situation.

If the polarity of your encoder is reversed, you can also switch the polarity in MAX. To change the polarity of your encoders, select the axis on which the problem is occurring and find the encoder entry. On the encoder tab change the polarity of either A or B, but not both and the index if it is being used.

- Cause 3: Improperly tuned PID loop in a servomotor system

Because NI servomotor controllers are designed for use in varied applications, the PID control loop must be configured for use in each specific situation. Properly tuning the loop (setting the

Kp, Kd, Ki, etc. parameters) in MAX is necessary to ensure that the motor will respond as expected. If the system responds to a command by vibrating or moving erratically, the control loop may be out of tune. Considerations for tuning your motion system can be found in

Understanding Servo Tune.

- Cause 4: Commanding a move that is too fast

A very high-velocity move requires a responsive motion system. If high-velocity or high-acceleration commands regularly result in following error conditions, the motor/stage setup may be incapable of reaching the target velocity or acceleration. (Causes vary widely, and could include excess friction, misaligned mechanical parts, or insufficient motor torque.) It may be necessary to adjust the mechanical setup or command a lower velocity/acceleration.